Our Mission

Providing leading edge technical products to the marine industry that improve the environment for boat owners, crew, guests and other water users.

Our Expertise

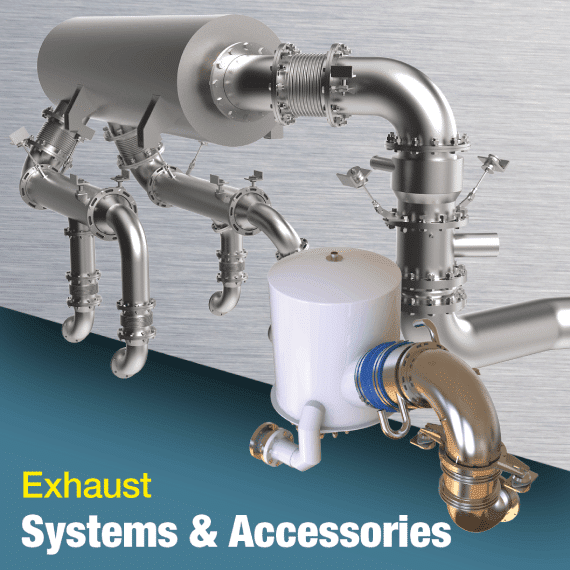

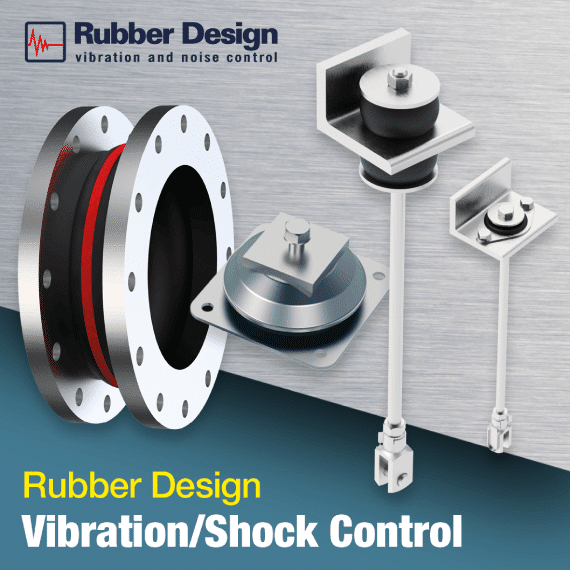

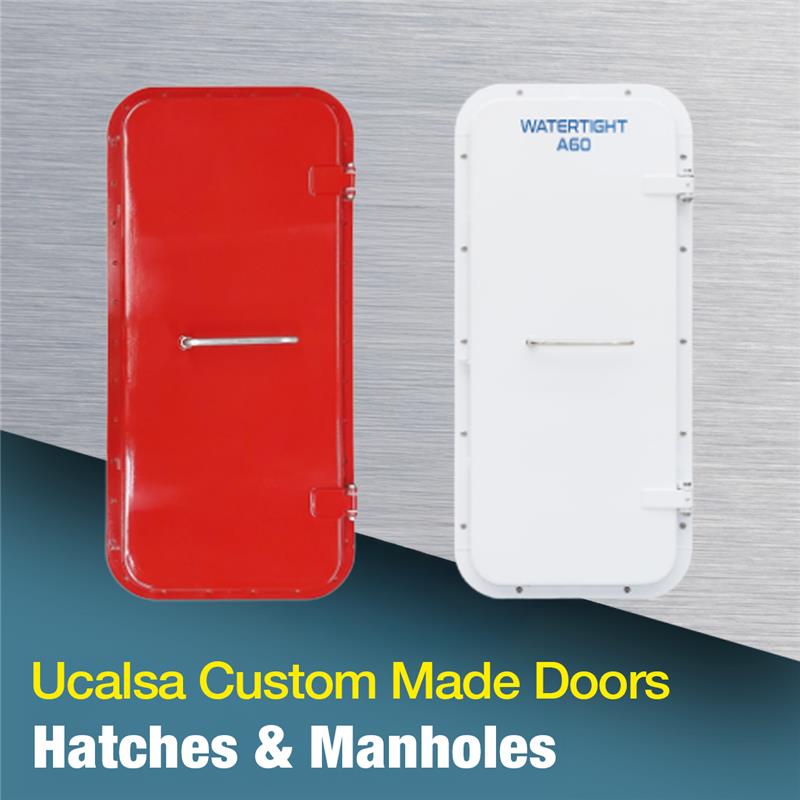

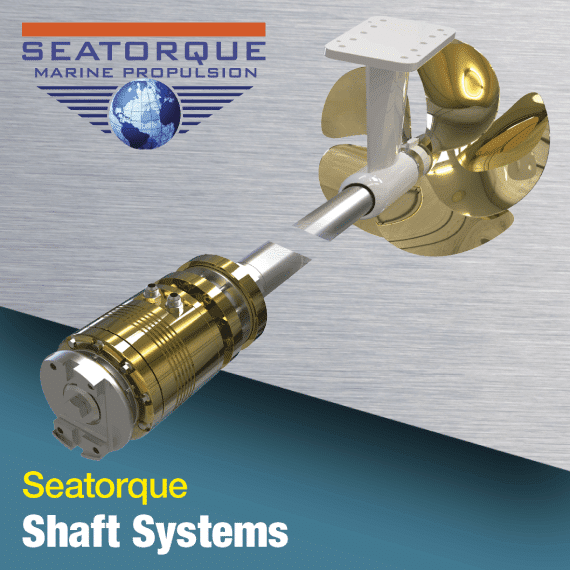

Providing consultation, design, and manufacturing of marine systems for yachts and commercial vessels.

- Established in 1979

- Global supplier of high quality technical marine products

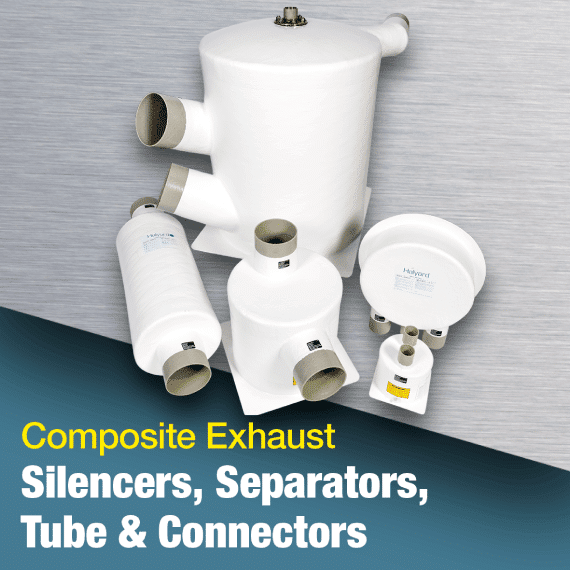

- One-stop shop with in-house design & manufacturing of Halyard exhaust systems and other products

- Distributor of high quality technical marine products

- Operate across Europe, Scandanavia, Asia, South Pacific & rest of world

- Consultative partnership customer strategy supporting optimised product/systems supply

- Experienced technical sales team with in-depth product and marine application knowledge

- Work to Marine Classification Society rules, LYC & PYC standards, RCD

- Global network of distributors, dealers & agents

- Aftersales support team

Markets We Serve

Our Process

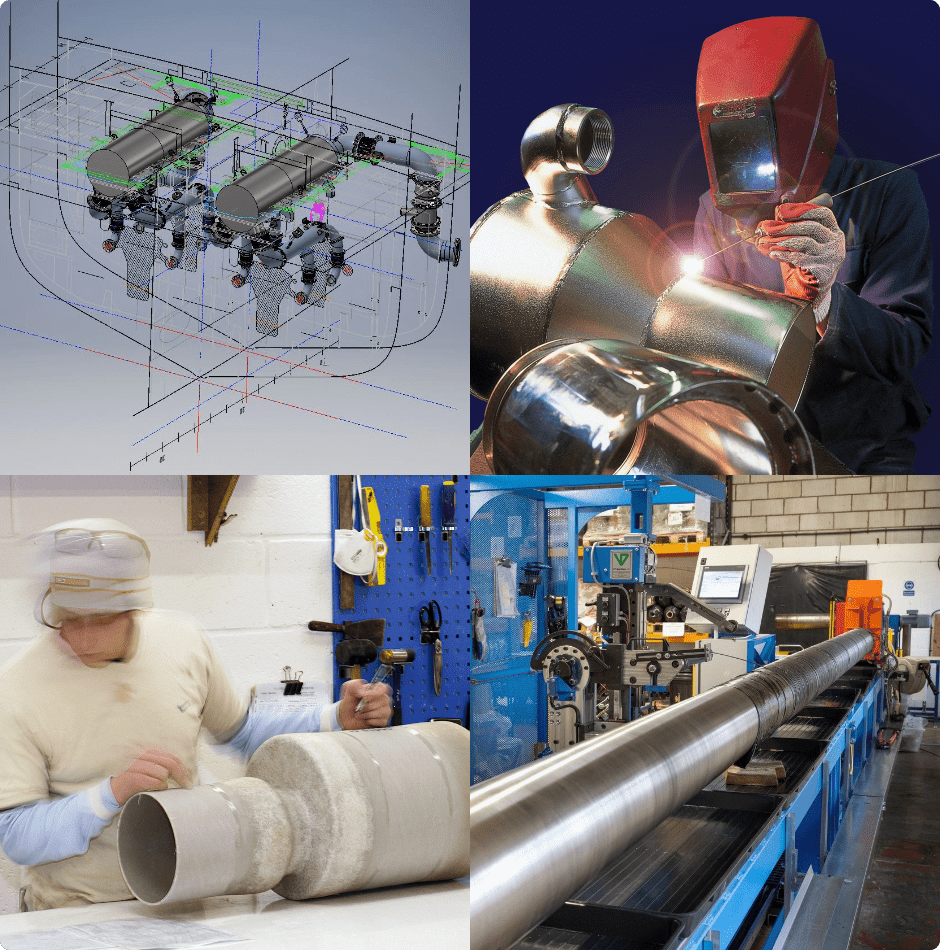

Consultation

We begin with a detailed consultation to understand our customers’ requirements and project objectives.

Design

Once agreed, we design to the brief, create detailed drawings and models for review, manufacture components in our Halyard facilities, and procure necessary parts.

Manufacturing

Depending on customer requirements, our services can extend to installation support, commissioning, and sea trials, with all relevant documentation and reports provided.

From consultation to design and manufacture, we ensure high-quality results at each stage

News

View how our solutions have supported various marine projects

FAQ’S

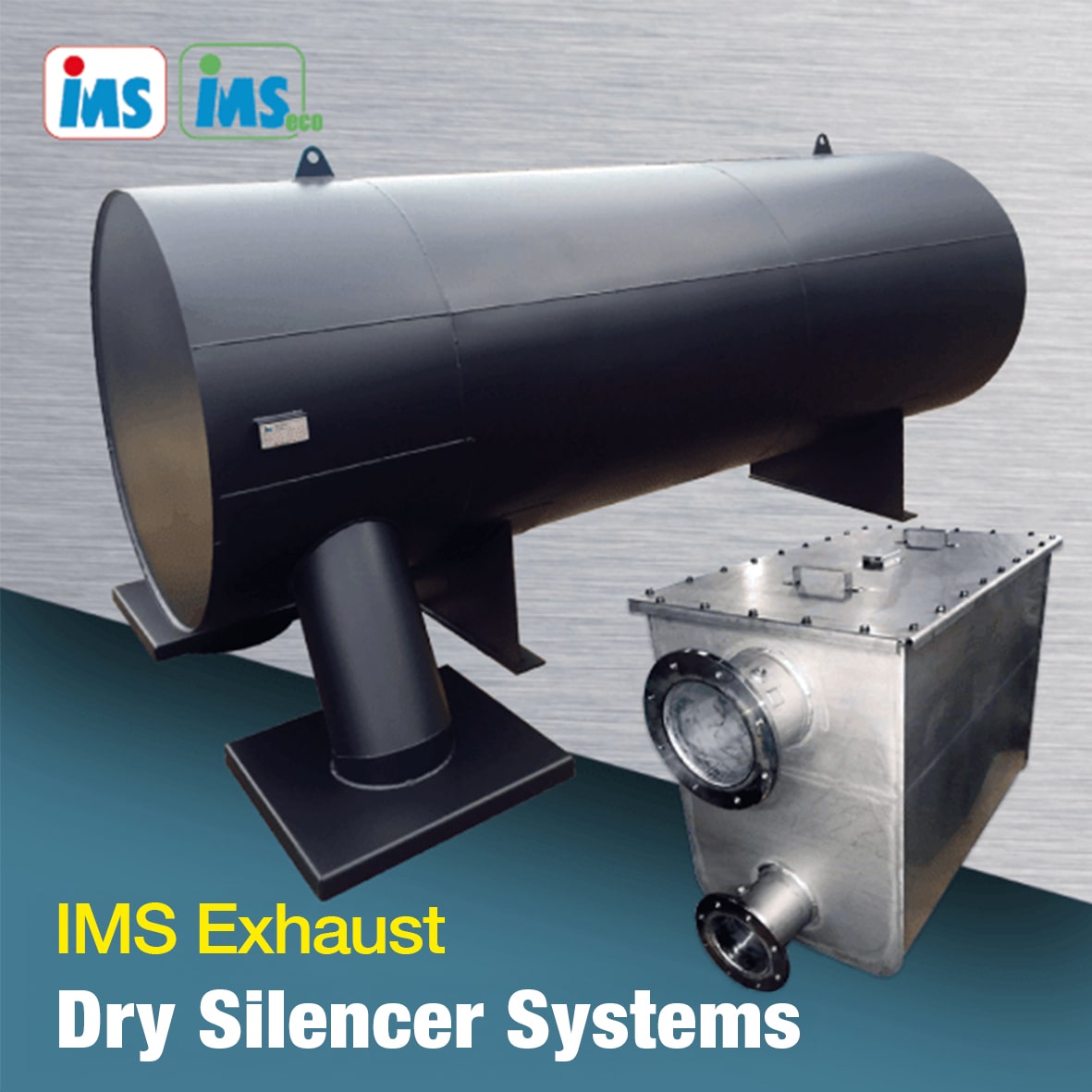

Yes, with in-house design and full system manufacture, Halyard can design and supply full water-cooled or dry exhaust systems to suit virtually any vessel. All that is needed is a 3D model/drawings of the engine room space from the engine turbo/manifold outlet and flange position to the intended vessel exhaust outlet position, plus the engine data sheet.

Generally, yes but would require at least a dimensioned sketch as a starting point. Once Halyard drawings are created full dimensions would need to be checked against the installation and approved by the customer.

Yes, we can manufacture using the existing equipment as a pattern to create a replacement or visit the vessel to measure for the replacement system.

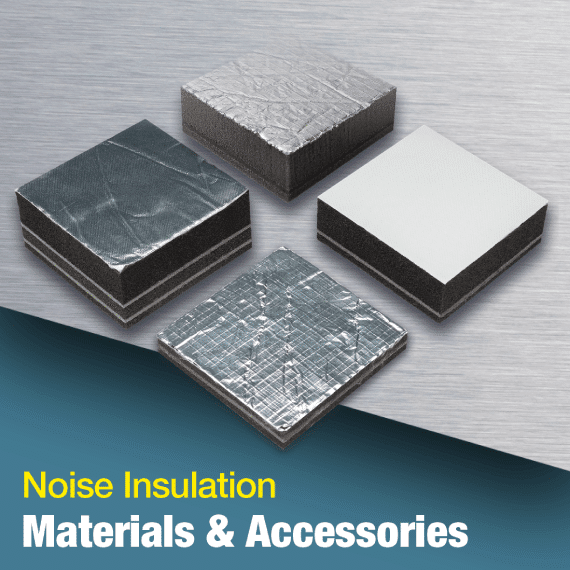

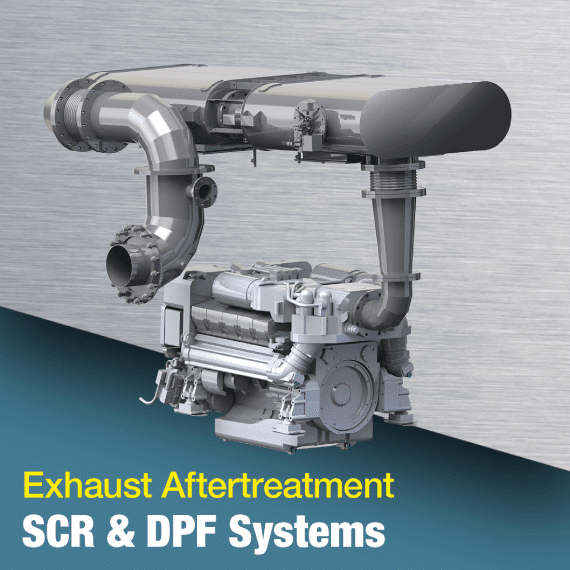

Yes, we have developed systems and use materials compatible with the increased temperatures generated by aftertreatment equipment.

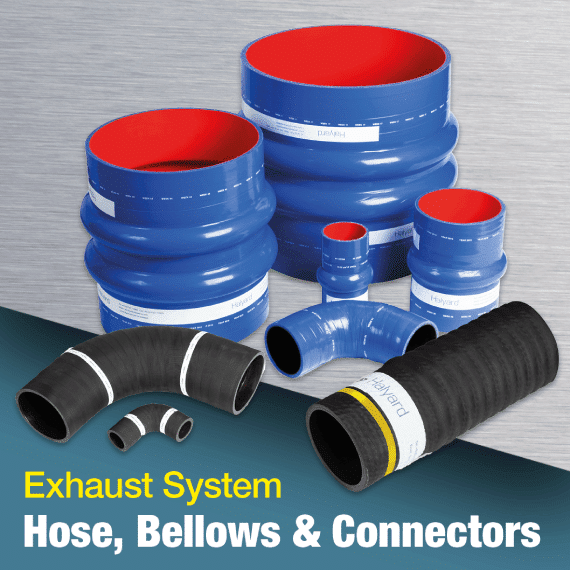

Halyard can specify to suit the particular application and its position in the exhaust system. Higher temperature hoses are generally closest to the spray head/aftertreatment systems.

Yes, we supply the Halyard “Exhaust Alert” system with both visual and audible alerts built into a standard 52mm diameter IP67 waterproof gauge and with fail safe functionality.

Yes, the Halyard OEM Control Box will support this integration to a vessel display.

Our exhaust alert is designed as a temperature switch to alert to a cooling water flow reduction/loss at a set temperature, it is not a thermocouple to provide the temperature reading.

Yes, we can supply replacement thermal jackets to a dimensioned drawing/sketch or normally from the original item.

Yes, dependant on the country location. Halyard has a service operation to support with installation, commissioning, vessel audits, fault finding, maintenance, repair or replacement for any exhaust system and not just Halyard supplied.

Yes, as a distributor for both the Halyard service team are OEM factory trained to offer full support for our distributed products.

Need Assistance?

Reach out to our support team for help with products, installation, or any inquiries.

Warranty & Aftercare

Our products come with warranties. For aftercare support, please contact us directly.

Technical Support

We provide technical support for all our systems. Please get in touch for troubleshooting or advice.

Document Downloads

Access manuals, datasheets, and product guides via our resource centre.